Raw Materials

by Nippon Co., Ltd.

Carbon Fiber Products

Carbon fiber that expands possibilities

Carbon fiber is produced by heat-treating special organic fiber and graphitizing it. Carbon fiber, on top of carbon’s various characteristics, has flexibility because the fiber is shapable. Therefore, carbon fiber is used in a wide range of fields such as aviation, space, electronics, automobile and energy industry.

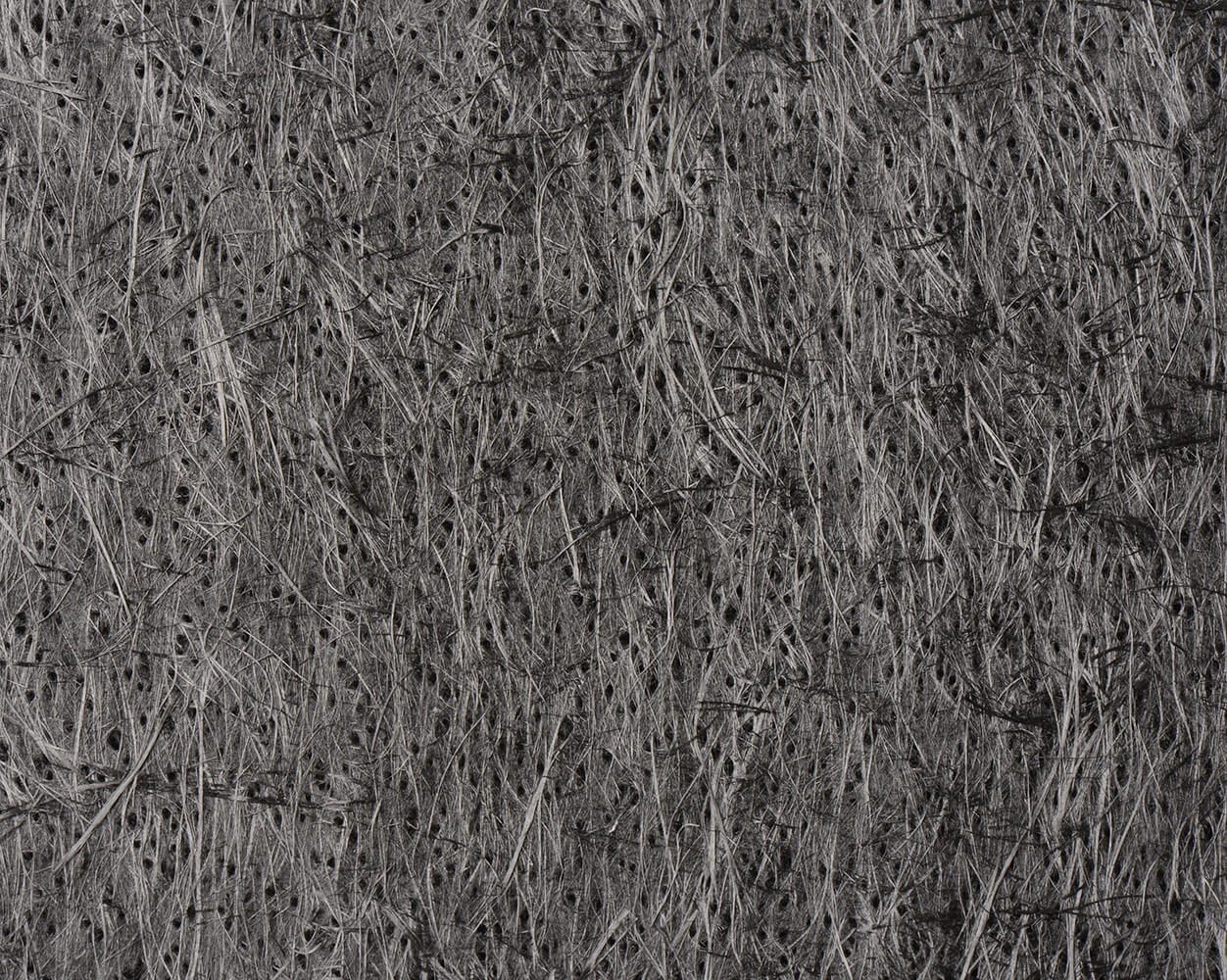

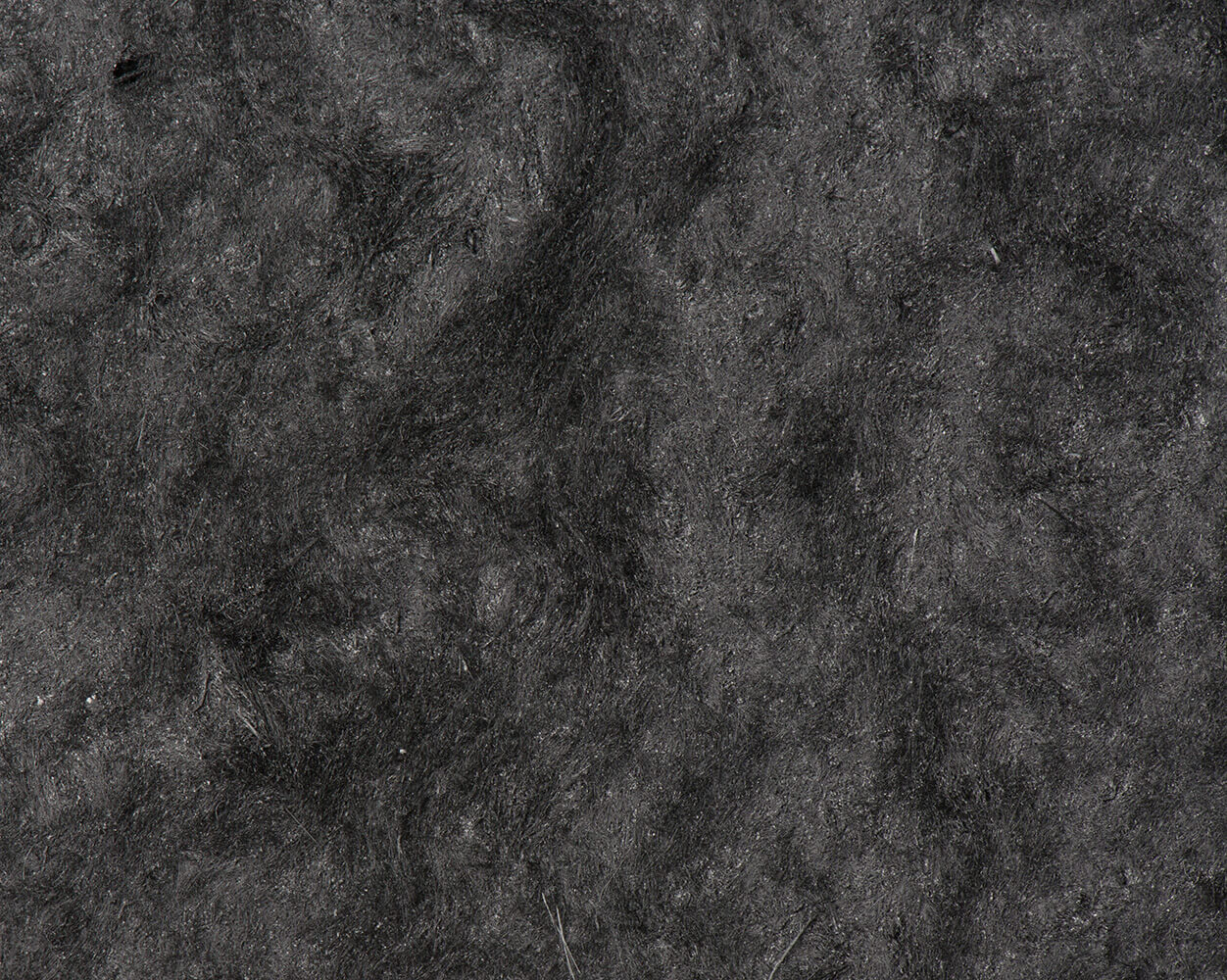

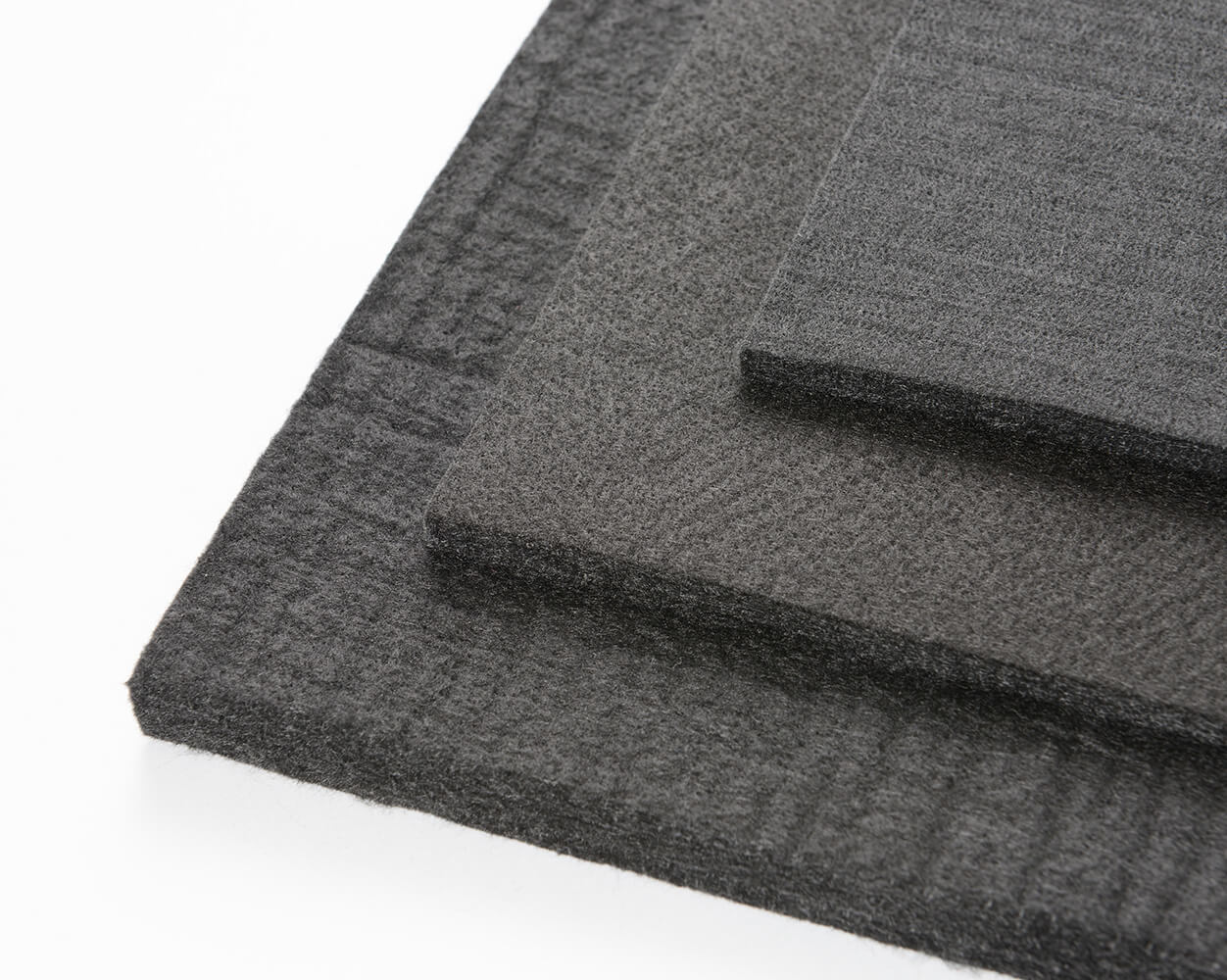

MOLDED HEAT INSULATING MATERIAL

Felt molded heat insulating material series FGL is usable in high temperature >2000°C, and excels in workability into various insulation shapes. High purity treated product is available for applications where impurities in the furnace chamber cannot be tolerated.

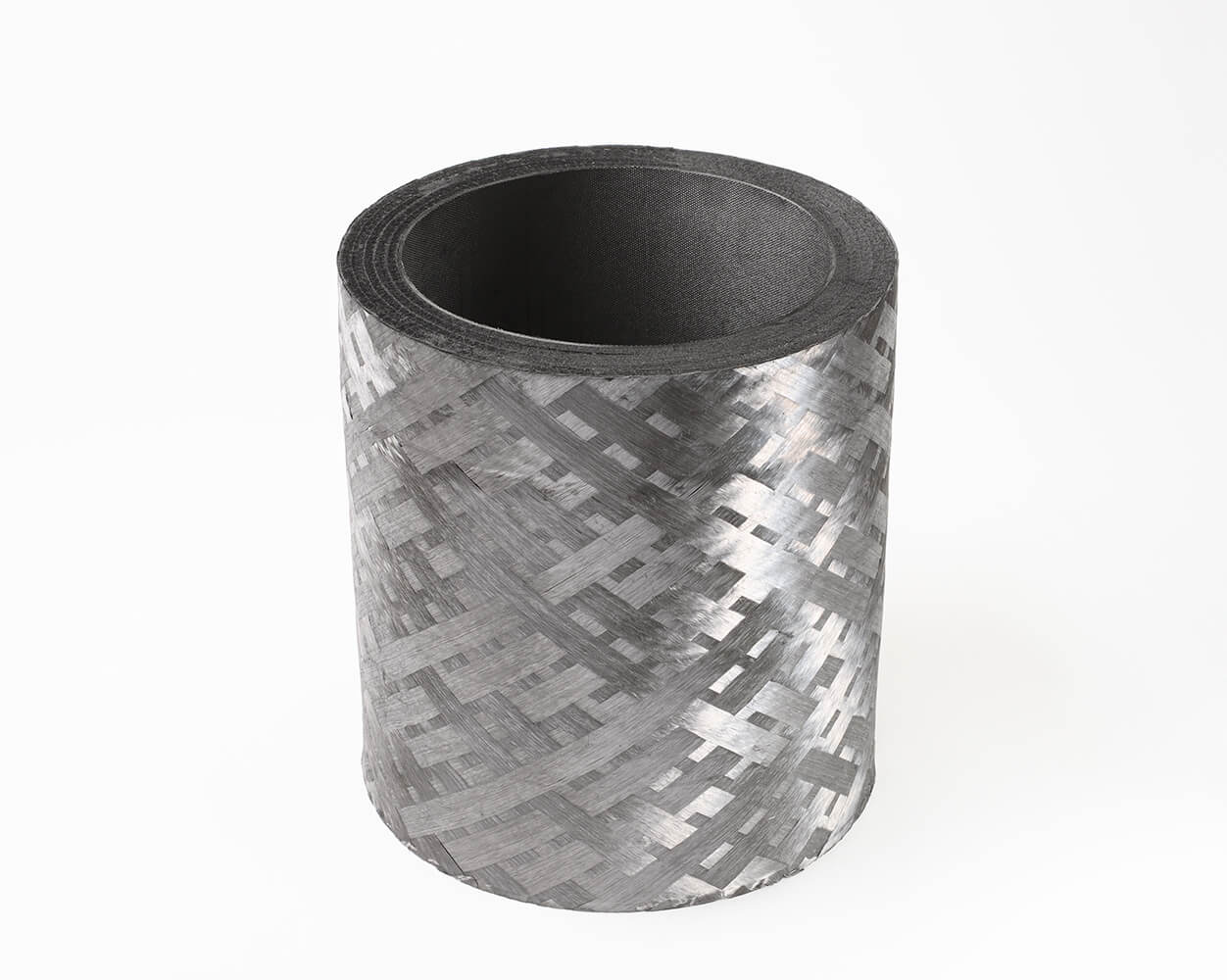

COMPOSITE (CCM ®)

CCM® is a lightweight carbon material that has high strength and elasticity, reinforced with carbon fibers. Since both the reinforced fibers and the matrix are composed of carbon graphite, CCM maintains carbon’s superior properties.

CARBON FIBER PACKING MAT. (CARBEST ®)

Carbon fiber packing material CARBEST ® is a composite material that has combined features of graphite fiber and Teflon. CARBEST ® is an excellent non-asbestos industrial material that has high heat resistance, corrosion resistance, abrasion resistance and thermal conductivity.

Specialty Carbon Products (Carbon Specialties)

Specialty Carbon Products (Carbon Specialties) are high-performance products that underlie the

development of key industries such as electronics, machinery and metallurgy, which are also used in cutting-edge fields of applied science such as semiconductors, aviation, and aerospace.

ISOTROPIC GRAPHITE

Isotropic graphite is the graphite material produced by CIP (Cold Isostatic Pressing) forming which eases machinability, making it desirable for a wide range of industrial purposes.

We have adapted to the needs of the latest technological areas with a long development history of providing the world-largest block sizes, for example with diameter >2000mm.

HIGH PURITY TREATMENT GRAPHITE

When crystal silicon, which provides a fundamental substance for semiconductors or solar batteries is produced, the manufacturing process requires a clean environment. High Purity Treatment Graphite in which all the impure substances are removed, is used for this purpose.

CARBON PRODUCTS FOR MECH. COMPONENTS

With the advantage of carbon’s excellent features of self-lubrication, chemical corrosion resistance and heat resistance, Carbon Products for Mechanical Components are used in various industries such as electronics, machinery and metals.

SILICON CARBIDE COATED PRODUCTS (VESCOAT®)

VESCOAT is produced by surface-coating high purity graphite material with high purity SiC (silicon carbide).

On top of its high oxidation resistance and chemical corrosion resistance, VESCOAT has several excellent soaking properties, size accuracy and flat and smooth surfaces. VESCOAT is used for silicon semiconductor, LED, and manufacturing device components for optical fibers.

SLIDING COMPOSITES (SC CARBON ®)

SC CARBON ® is produced by vacuum pressure impregnation of metal or resin into carbon material to increase and improve its mechanical strength and sealing ability.

In addition to this, base carbon materials are designed to make a perfect combination with metal or resin. The product possesses excellent mechanical strength, sliding properties and abrasion resistance.

NEW:

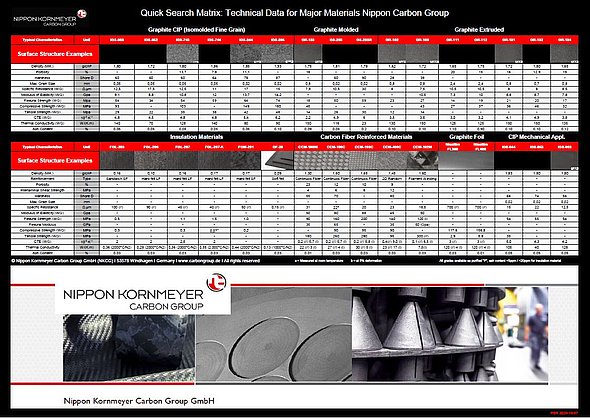

NKCG Raw Material Quick Search Matrix