Quality

We at NKCG combine Japanese raw material quality and German craftmanship!

Quality is the task of every NKCG team member. In addition, NKCG maintains a document control system in accordance with ISO standards. Records and reserve samples can be retained for up to 10 years upon request. Our products are inspected, assessed and subjected to stringent testing at every individual stage of our manufacturing process.

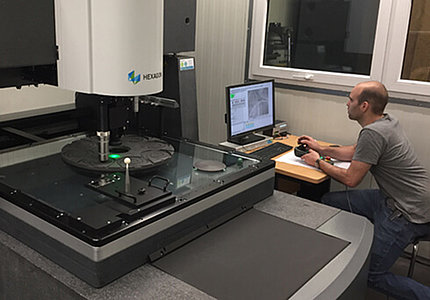

Our equipment:

3D multi-sensor coordinate Measuring Machine Hexagon Optiv Reference 10103 Dual Z

- Tactile measurement of the material shape (2D/3D) Optical measurement (projector)

- White-light sensor to analyze roughness and surface profile

- Measuring area: X 1000 mm Y 930 mm Z 300 mm

Integrated measuring system CNC machines

- CNC machines are equipped with integrated systems for confirming size accuracy of the material throughout the manufacturing process.

Faro 7 axis arm

- Measurement of dimensional, form and positional tolerances

CAQ Software

- Quality Planning

- Quality Assurance

- Quality Management

Upon request

- 100% inspection & tracing

- APQP

- SPC

- FMEA